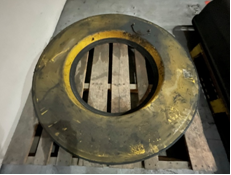

Dismantled parts from PC200-8M0.

The Cover of the Swing Circle in the Komatsu PC200-8M0 excavator is a protective shield designed to cover and safeguard the swing circle (also known as the swing bearing or swing gear). This cover is an essential part of the excavator's structure, helping to protect the swing circle from external elements and ensure its smooth operation. Here’s a detailed description:

1. Material:

- The swing circle cover is typically made from high-strength steel or heavy-duty metal, designed to withstand the harsh conditions of construction sites. The material must be durable enough to protect the swing bearing from debris, impacts, and environmental wear while resisting corrosion and weather damage.

2. Function:

- Protection: The primary function of the swing circle cover is to protect the swing bearing and its internal components, including the gears and rollers, from dirt, dust, rocks, and other debris that could impair their performance or cause wear.

- Seal Against Contaminants: It helps prevent water, mud, and other contaminants from entering the swing bearing assembly. These contaminants could lead to premature wear, rust, or failure of the swing circle if left unchecked.

- Safety: The cover also prevents accidental contact with moving parts within the swing bearing, which could pose a risk to maintenance personnel during operation or servicing.

- Structural Integrity: The cover contributes to the overall structural stability of the swing circle by holding components in place and preventing unnecessary movement of parts, ensuring smooth and consistent rotation of the upper structure.

3. Design:

- Shape and Fit: The cover is typically circular or slightly contoured to match the shape of the swing circle. It is designed to fit snugly over the swing bearing, providing full coverage while allowing for movement and rotation underneath.

- Seals and Gaskets: Often, the cover includes seals or gaskets around its edges to create a tight fit and further prevent contaminants from entering the bearing assembly. These seals also help reduce the likelihood of oil or grease leaking out from the swing bearing.

- Mounting Bolts: The cover is usually secured with bolts around its perimeter, which hold it in place on the frame of the excavator. These bolts are typically easy to remove for maintenance or inspection of the swing circle.

4. Location:

- The swing circle cover is mounted over the swing bearing between the excavator's upper structure and the undercarriage. It is located underneath the machine, protecting the swing bearing from below and providing a barrier between the ground and the bearing system.

5. Maintenance:

- Inspection: Regular inspection of the swing circle cover is important to check for any damage, such as cracks, dents, or loose bolts. Damage to the cover could expose the swing bearing to harmful debris or moisture, leading to potential failure.

- Replacement: If the cover becomes compromised (cracked or excessively worn), it should be replaced to ensure continued protection of the swing circle and to prevent contaminants from entering the swing bearing assembly.

- Cleaning: Periodically cleaning the cover and the area around it helps to remove buildup of dirt or debris that could potentially find its way into the swing bearing.

6. Safety:

- The swing circle cover is an important safety feature that prevents large debris, stones, or other objects from getting trapped in the swing bearing, which could jam the system or cause damage. It also protects workers from accidental contact with the moving swing bearing during maintenance operations.

7. Role in Performance:

- By keeping the swing circle clean and protected, the cover helps maintain the smooth rotational movement of the upper structure of the excavator. A damaged or missing cover could lead to contamination of the bearing, causing it to seize or perform poorly, which in turn would affect the excavator’s ability to swing and operate effectively.

Summary:

The Swing Circle Cover of the Komatsu PC200-8M0 is a robust protective component that shields the swing bearing from external contaminants, such as dirt, rocks, water, and dust. It helps maintain the integrity and performance of the swing system by preventing wear and damage to the swing bearing. Constructed from durable materials, it is designed to fit securely over the swing bearing and is crucial for ensuring smooth rotation, safety, and longevity of the excavator’s swing mechanism. Regular inspection and maintenance of the cover are essential to ensure it continues to provide optimal protection.