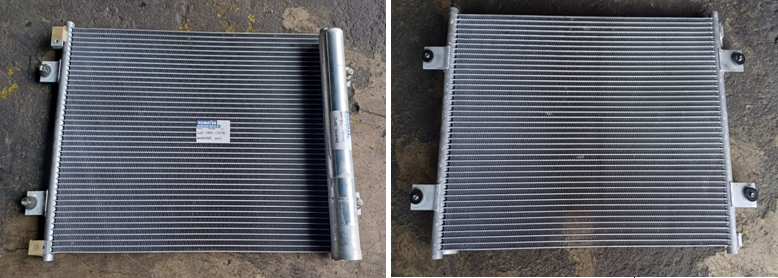

Dismantled parts from PC200-8M0 C22176 and PC200LC-8M0 C15621.

The Condenser Assembly of the Komatsu PC200-8M0 excavator is a vital part of the machine's air conditioning (A/C) system. Its primary role is to facilitate the cooling of the refrigerant used in the system, ensuring efficient heat dissipation and maintaining the desired temperature inside the operator’s cabin.

Here’s a detailed description of the Condenser Assembly:

1. Functionality

- The primary function of the condenser is to remove heat from the high-pressure refrigerant gas, converting it into a high-pressure liquid. This process allows the air conditioning system to provide cool air inside the cab.

- It plays a critical role in the A/C cycle by enabling the refrigerant to release the heat it absorbed from the cabin air, thus contributing to the system's overall cooling efficiency.

2. Components

The condenser assembly typically consists of several key components:

- Condenser Core (Coils): This is the central part of the assembly where the refrigerant passes through and cools down. The core is made up of tubes (often aluminum or copper) and thin fins, which help dissipate heat.

- Fins: These are metal strips attached to the condenser tubes, designed to increase the surface area for heat dissipation and enhance the cooling process.

- Inlet and Outlet Ports: These ports connect the condenser to the rest of the A/C system, allowing refrigerant to flow in and out of the assembly.

- Fan (Optional): Some condenser assemblies are equipped with an electric fan to improve airflow through the fins and accelerate the cooling process, particularly when the excavator is stationary or in low-speed operation.

- Mounting Brackets: These are used to securely attach the condenser to the excavator's frame or near the radiator.

3. Operation

- The condenser works as part of the air conditioning cycle. After the refrigerant absorbs heat from the cabin, it becomes a high-pressure, high-temperature gas. This gas flows into the condenser, where it releases the absorbed heat.

- As the refrigerant passes through the coils and fins of the condenser, it cools down and changes from a gas into a liquid, which is then cycled back into the system to continue the cooling process.

4. Cooling Process

- The condenser assembly is usually placed in front of the radiator to take advantage of the airflow generated by the excavator’s movement or the radiator fan. This airflow helps cool the refrigerant inside the condenser coils.

- In some cases, an auxiliary fan may be attached to the condenser to ensure sufficient airflow, especially when the machine is operating in hot environments or when there is limited airflow due to stationary operation.

5. Materials

- The condenser is typically made from lightweight and durable materials such as aluminum or copper, which provide excellent thermal conductivity for efficient heat transfer while being resistant to corrosion.

- The fins are usually made from thin metal sheets to maximize heat dissipation and improve overall cooling performance.

6. Location and Integration

- The condenser is generally located at the front of the excavator, near the engine compartment, where it can benefit from the flow of air. It is strategically placed alongside or in front of the radiator to optimize cooling performance.

- It is integrated into the A/C system between the compressor and the expansion valve, where it plays a key role in converting the high-pressure refrigerant gas into a liquid.

7. Maintenance

- Regular inspection and maintenance of the condenser assembly are crucial for optimal A/C system performance. This includes:

- Cleaning the Fins: Dirt, debris, or dust can accumulate on the fins, reducing the condenser’s efficiency. Regular cleaning ensures proper airflow and heat dissipation.

- Checking for Leaks: Over time, refrigerant leaks may develop at the joints or tubes. Checking for leaks and ensuring proper sealing is vital for maintaining system performance.

- Inspecting the Fan (if applicable): If the condenser has an auxiliary fan, it’s important to ensure the fan is functioning correctly to provide additional cooling when needed.

8. Operating Conditions

- The condenser assembly is designed to handle the high pressures and temperatures associated with the refrigerant in its gaseous state. It must operate efficiently across a wide range of temperatures and environmental conditions to ensure the A/C system works properly in various climates.

Function:

The Condenser Assembly serves a critical function in the air conditioning system of the Komatsu PC200-8M0 excavator by:

- Releasing Heat: It cools down the high-temperature refrigerant gas and condenses it into a liquid, allowing the A/C system to function efficiently.

- Supporting Cooling Efficiency: It ensures that the refrigerant is ready to circulate back through the system to provide continuous cooling in the cabin.

Benefits:

- Improved Cabin Comfort: By efficiently cooling the refrigerant, the condenser assembly ensures that the air conditioning system can maintain a comfortable temperature inside the cabin, even in hot or demanding working environments.

- Energy Efficiency: A well-functioning condenser reduces the workload on the compressor, leading to better overall energy efficiency for the air conditioning system.

- Durability: Constructed from materials that can withstand the pressures and temperatures of the A/C cycle, the condenser is designed for long-term reliability and performance.

Importance:

The Condenser Assembly is a crucial component in the Komatsu PC200-8M0 excavator’s air conditioning system. It enables efficient heat dissipation from the refrigerant, ensuring the A/C system provides reliable cooling for the operator. Regular maintenance, such as cleaning the fins and inspecting for leaks, is essential to keep the condenser functioning properly and avoid reduced cooling performance or system failures.

By maintaining optimal refrigerant temperature, the condenser assembly ensures the excavator can operate comfortably and efficiently in a variety of working conditions.